UR SERVICE OFFERINGS

UR Care

UR Care

As a trusted partner, Universal Robots is committed to your success starting with UR Care. Begin with the formalized myUR registration and support ticketing system, direct engagement with your specific questions, and comprehensive on-line training in the UR Academy which helps a robotic layperson become familiar with core concepts, nomenclature, and commands.

UR Insight

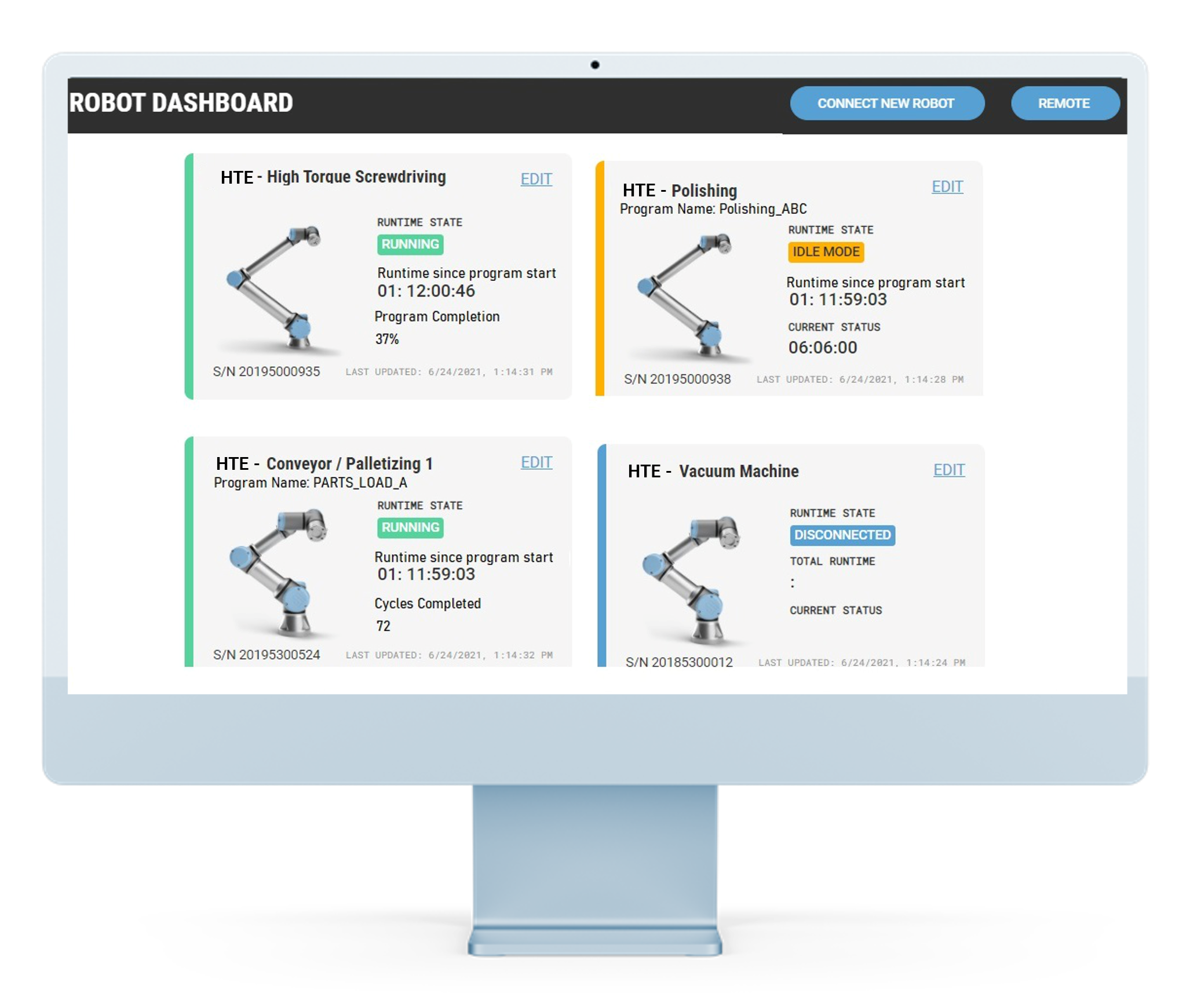

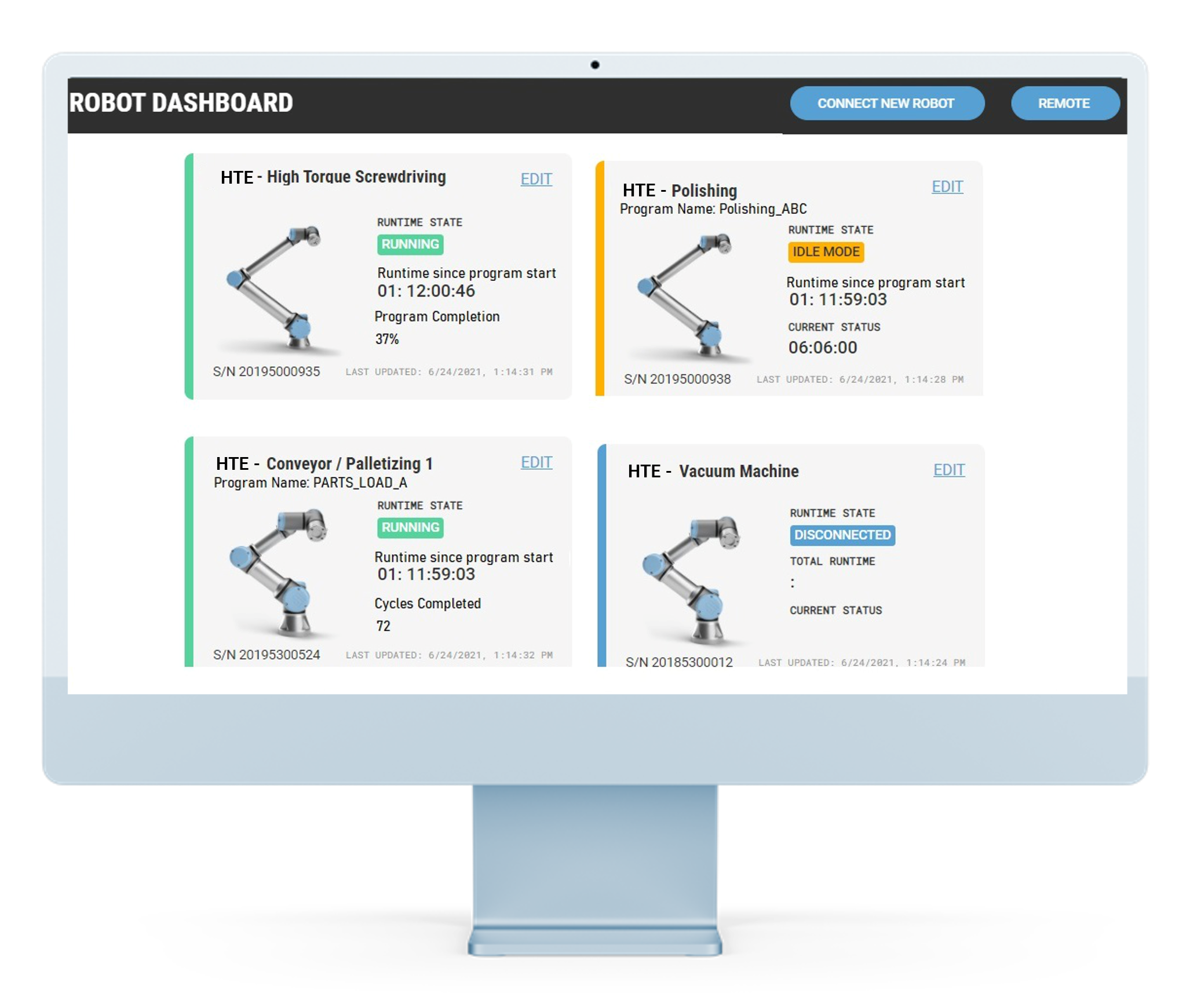

Great decisions require accurate insights gained from detailed knowledge. To the support provided in UR Care, the UR Insight level of service adds myUR Monitoring with which you track cycle times and cycle counts in real time, directly from your smart device. To alert you of significant events, you can receive notifications for robot stops, alarms and application-specific events regardless of your global location. When you are at your computer, the Dashboard will monitor multiple robot workcells, all on one dashboard, and accessible from any networked computer. For a deeper understanding through close examination of that monitoring, the Log Reports functionality allows you to diagnose production inefficiencies and gain a full understanding of your productivity through exportable/downloadable log reports.

UR Performance

This top service level adds to everything included in UR Care and UR Insight. It is designed to optimize the performance of your robot over many years through Annual Cobot Performance Checks resulting in specific practical and actionable recommendations. These check-ups are done remotely without disrupting production.as UR tracks, schedules, and reminds you of each upcoming performance check, keeping your staff focused on running your business. The check-up will result in a list of recommendations, each designed to maximize the cobot's uptime, and lifespan.

HTE SUPPORT

HTE Automation and Universal Robots are committed to maximizing your productivity through the ongoing service and support of all the productivity solutions we offer. HTE Automation supports manufacturers in Kansas, Missouri, and Illinois.

For more than 60 years HTE has been serving the Kansas, Missouri and Illinois manufacturing community, and we remain dedicated to providing a high level of local service as we work with you to maximize your productivity.

To be effective, our service and support team must gain a comprehensive understanding of your production plant's needs and goals. To start learning, we offer a complimentary plant walk-through by one of our seasoned automation specialists, followed by an in-depth discussion to ensure that we correctly understood what we observed. For years to come we expect our team to stay informed about your plant's changing goals and ongoing challenges.

ROBOT LAB

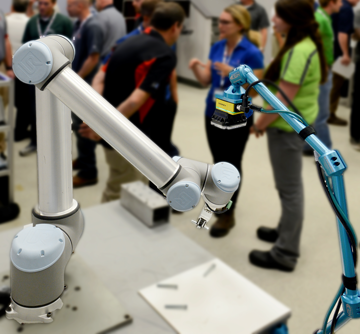

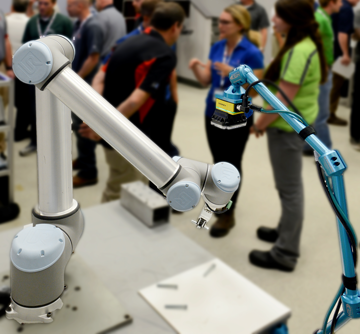

In the case of a robotics project, our team of experienced automation engineers and technicians will work in our robot lab to prove which robot model most cost-effectively delivers on your stated production, safety, or operational goals. We refer to this as the proof-of-concept stage.

Our experienced staff of robotics specialists excel when it comes to selecting, or designing accessories and tools that will empower your robot. That process starts with choosing or creating the optimal end of arm tooling, or EOAT, for your application.

One of the most exciting developments in recent years has been the cost-effective implementation of machine vision cameras with robotics. It is now possible for your robot to actually see and respond to variable location targeted items.

Our robot laboratories also provide an environment for your staff to engage directly with our robots. It is here that many customers have gained a greater appreciation for the equipment's capabilities, and for our staff's ability to maximize the value delivered for each application as they become familiar with equipment before having to make a commitment to buy it.

ROBOT LEASING

Paying for automation projects has been the traditional domain of budgeting committees, however, that is all changing as core components such as Collaborative Robots retain their value outside of a customized project. Cobots can easily be retasked, and rarely require extensive safety guarding, all of which would traditionally be unique to a specific project. As a result, rather than allowing your budget process to delay implementation of a rapid ROI project, cobots, unlike traditional robots, can be acquired via a lease, or even on rent-to-own terms.

ROBOT TRAINING

ROBOT TRAINING

All the adaptive power of a cobot can be managed without a robotics engineer by your current production staff. They do not need extensive multi-year robotics training. The UR Core Training Program starts with 87 minutes spent online, and then enrolling in a 2-day class held at HTE's Universal Robots Authorized Training Centers in either Kansas City or St. Louis, or in Wichita at the National Insitute of Aviation Research. These classes are very limited in size and provide 1 collaborative robot for every 2 students, maximizing the hands-on value of the robot class. For more details on our Certified Universal Robots Training program

click here.

HTE is here for the long haul, ready, staffed, and resourced to serve the

Kansas, Missouri, and Illinois manufacturing communities with ongoing product life-cycle support that is second to none.

Contact us at 800-444-4831 with any questions about your automation needs, and remember, we will be happy to take the time to join you on a walk-through of your production area to better serve you.

UR Care

UR Care

HTE Automation and Universal Robots are committed to maximizing your productivity through the ongoing service and support of all the productivity solutions we offer. HTE Automation supports manufacturers in Kansas, Missouri, and Illinois.

HTE Automation and Universal Robots are committed to maximizing your productivity through the ongoing service and support of all the productivity solutions we offer. HTE Automation supports manufacturers in Kansas, Missouri, and Illinois.

To be effective, our service and support team must gain a comprehensive understanding of your production plant's needs and goals. To start learning, we offer a complimentary plant walk-through by one of our seasoned automation specialists, followed by an in-depth discussion to ensure that we correctly understood what we observed. For years to come we expect our team to stay informed about your plant's changing goals and ongoing challenges.

To be effective, our service and support team must gain a comprehensive understanding of your production plant's needs and goals. To start learning, we offer a complimentary plant walk-through by one of our seasoned automation specialists, followed by an in-depth discussion to ensure that we correctly understood what we observed. For years to come we expect our team to stay informed about your plant's changing goals and ongoing challenges. In the case of a robotics project, our team of experienced automation engineers and technicians will work in our robot lab to prove which robot model most cost-effectively delivers on your stated production, safety, or operational goals. We refer to this as the proof-of-concept stage.

In the case of a robotics project, our team of experienced automation engineers and technicians will work in our robot lab to prove which robot model most cost-effectively delivers on your stated production, safety, or operational goals. We refer to this as the proof-of-concept stage.

Our experienced staff of robotics specialists excel when it comes to selecting, or designing accessories and tools that will empower your robot. That process starts with choosing or creating the optimal end of arm tooling, or EOAT, for your application.

Our experienced staff of robotics specialists excel when it comes to selecting, or designing accessories and tools that will empower your robot. That process starts with choosing or creating the optimal end of arm tooling, or EOAT, for your application.

ROBOT TRAINING

ROBOT TRAINING